What Crucibles Are Used in Thermal Analysis Applications?

Choosing the wrong crucible in thermal experiments can ruin precise results or even damage equipment.

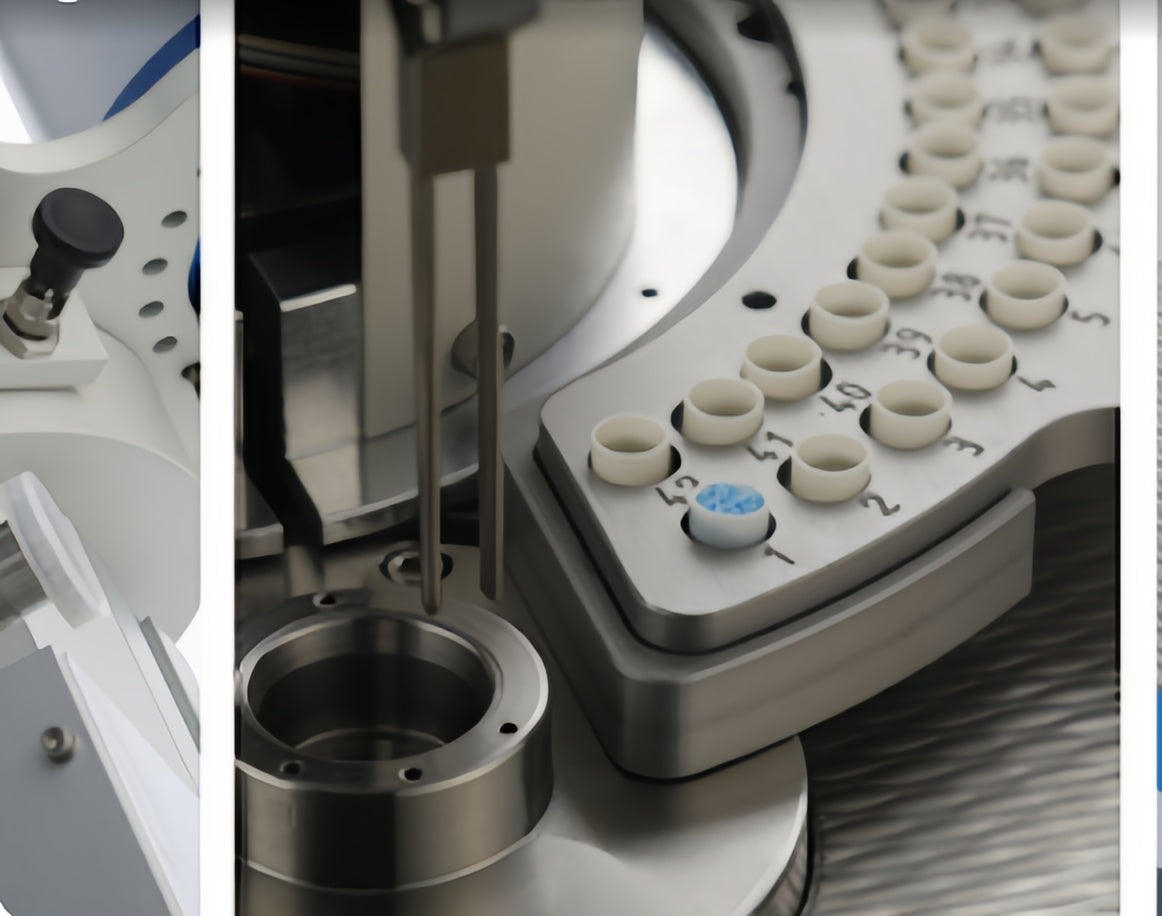

Crucibles in thermal analysis serve to contain samples and transfer heat efficiently. Their material affects heat flow and may react with the sample. Common types include platinum, alumina, zirconia, graphite, and aluminum. Each material offers different levels of temperature resistance, reactivity, and cost.

In my daily conversations with lab customers, one thing is clear: choosing the right crucible improves test repeatability and ensures more consistent data. This becomes especially critical in DSC, TGA, and DTA experiments where thermal conductivity and chemical stability matter most. Whether you're working in pharmaceuticals, energy materials, or advanced research, this guide helps you select the ideal crucible for your thermal analysis needs.

What is a crucible used for in thermal analysis?

A thermal analyzer is only as accurate as the crucible that holds the sample.

In thermal analysis, a crucible holds the sample during heating or cooling and ensures accurate and uniform thermal contact. It must remain stable at high temperatures while avoiding reactions with the sample.

How Crucibles Work in Thermal Analysis

| Function | Description |

|---|---|

| Sample Encapsulation | Securely holds sample to ensure repeatable mass and shape |

| Heat Transfer | Conducts thermal energy between chamber and sample |

| Chemical Isolation | Prevents reactions with air, moisture, or crucible material |

| Data Consistency | Uniform geometry ensures consistent baseline and accurate results |

Many first-time buyers, especially from university labs, underestimate the effect crucible fit has on results. Even a 0.1 mm deviation in size can disturb the thermal profile and skew measurements.

Which industries rely on thermal analysis crucibles?

Thermal analysis is not for every industry, but for those that depend on it, crucibles play a key role.

Any field conducting thermal stability studies or materials research requires high-quality thermal crucibles. These include pharmaceuticals, battery materials, ceramics, semiconductors, and aerospace R&D.

Industry Use of Thermal Analysis Crucibles

| Industry | Application | Preferred Material |

|---|---|---|

| Materials Science | Thermal capacity, crystal phase transitions | Alumina, zirconia, ceramic |

| Pharmaceuticals | Drug stability and decomposition profiling | Platinum, aluminum |

| Battery R&D | Decomposition and weight loss analysis | Ceramics, platinum |

| Academic Labs | General chemical and thermal analysis education | Aluminum, platinum, ceramic |

| Third-Party Testing | QA testing with multiple simultaneous experiments | Aluminum, stainless steel |

In my experience, pharmaceutical labs prefer platinum crucibles due to their purity and stability, while energy companies lean toward ceramic crucibles for high temperature endurance at lower cost.

How does crucible material affect thermal analysis results?

A crucible is not neutral—it directly affects accuracy, baseline, and test repeatability.

The material’s thermal conductivity, resistance to high temperature, and chemical stability all influence how a sample heats and reacts. The wrong crucible can cause peak shifts, secondary reactions, or measurement errors.

Material Properties and Their Experimental Impacts

| Material | Key Advantages | Best Use Cases | Limitations |

|---|---|---|---|

| Platinum | High inertness, thermal stability | DSC for pharmaceuticals or high-purity samples | Very expensive |

| Aluminum | Low cost, fast heat response | Routine DSC testing | Low melting point, reactive with some samples |

| Alumina | High thermal resistance | Battery and oxide materials, ceramics | Lower heat conductivity than metals |

| Zirconia | Stable at extreme temperatures | Advanced TGA analysis of refractory materials | Brittle, slightly more expensive |

| Graphite | Excellent thermal properties | Inert atmosphere or vacuum testing | Oxidizes in air above 400°C |

Every customer I work with wants reliable data. I always recommend determining baseline testing with multiple crucibles of the same batch and saving serial numbers for traceability.

What are the advantages of using platinum vs. ceramic crucibles?

What makes platinum worth the price, compared to ceramic crucibles?

Platinum crucibles provide superior thermal conductivity and chemical stability. They’re essential for high-precision DSC or TGA, where every microgram and °C counts. Ceramic crucibles are more affordable but offer decreased response speed and can chip or crack more easily.

Platinum vs. Ceramic Crucibles: A Side-by-Side Comparison

| Property | Platinum | Ceramic |

|---|---|---|

| Max Temperature | ~1700°C | 1600–1800°C (depends on type) |

| Thermal Conductivity | High, very responsive | Moderate, slower heat transfer |

| Chemical Inertness | Excellent in most conditions | Good, except with some acids |

| Durability | Very high, reusable many times | Moderate, prone to chipping |

| Cost | Very expensive | Affordable |

One German lab I worked with switched from standard ceramic crucibles to customized platinum ones for ECM (extracellular matrix) samples. This reduced thermal noise by over 40% and improved data reproducibility across days and devices.

Conclusion

Crucibles may be small, but picking the right material makes a big difference in thermal analysis accuracy and consistency.

Leave a comment